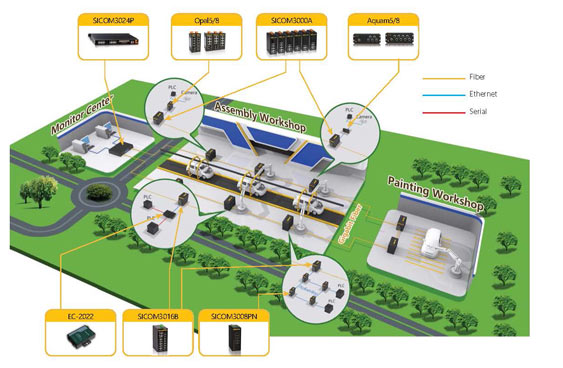

In modern automobile manufacturing system, a brand new car is made of multiple parts after stamping, welding, painting, assembling process. The automated production lines are replacing human workforce and workers can supervise the whole process in monitor center.

Reliable and stable network equipment, to ensure monitoring of the automobile manufacturing process

Limit installation space required

Redundant network capacity for fast failover recovery

Industrial design suitable to production lines environment

Easy device fault location, status display, and management

To provide access for devices in production lines including PLC, camera and other equipment.

Support industrial Ethernet protocol, providing network redundancy and management function

Industrial Ethernet switches with long MTBF to construct reliable communication network

Support IEC62439-6/DRP, DT-Ring, RSTP network redundancy, up to<20 ms recovery time

EMC level 3, IP30, fanless design, wide operating temperature

Kyvision NMS provides easy and reliable network monitoring and trouble shooting

Industrial embedded PC for access and control of end devices with serial, DI/DO connection

Industrial Profinet switches for industrial Ethernet network supporting Profinet v2.32, CC-B and IEC62439-2 MRP.

Based on Intel® high performance processor, which brings the whole system stability and fast response.